Executive Summary (Key Takeaways)

- ✓ Efficiency: Switching topologies achieve 90%+ efficiency vs. Linear's 50%.

- ✓ Integration: Industrial power supplies must support SCPI protocols via LAN/RS485.

- ✓ Reliability: "Industrial Grade" is defined by 100% duty cycle at 40°C ambient temp.

In the domain of industrial manufacturing and aerospace R&D, the term "generic power supply" is a liability.

Professional engineers understand that a variable AC DC power supply is not merely an energy source—it is a precision instrument. Whether validating SiC (Silicon Carbide) inverters for electric vehicles or managing gigawatt-scale electrolysis, the stability, transient response, and thermal management of your DC source dictates the validity of your data.

This technical archive updates the 2026 standards for selecting DC variable sources.We move beyond basic Ohm's Law to discuss System Integration, Programmable Logic Control (PLC) via SCPI, and the critical distinction between "Consumer Grade" and "Industrial Grade" reliability.

Key Features

Safety First

OVP, OCP, and OTP protection standards for 2026 lab environments.

Digital Control

USB-C, LAN, and AI-assisted voltage tracking capabilities.

Global Voltage

Active PFC ensuring stable operation on 110V or 220V grids worldwide.

Quick Selection Matrix: Matching Specs to Application

| Application | Voltage | Current | Recommended Series | Engineering Notes |

|---|---|---|---|---|

| EV Battery Management (BMS) Test | 0-150V | 0-3A / 0-5A | eTM-L1503SPL (Programmable) | High voltage essential. Programmable OVP/OCP required for safety. |

| Electroplating & Electrolysis | 0-15V / 0-30V | 0-200A+ | eTM-30200 / eTM-15100 | Requires high current density and 24/7 duty cycle capability. |

| Industrial Automation & Motor Driving | 0-60V / 0-80V | 0-50A | eTM-3050U (3U Rack) | Rack-mount form factor for ATE cabinets. RS232/485 control essential. |

| Mobile/Laptop Repair & Logic Testing | 0-30V | 0-10A | eTM-305 / eTM-3010 | Low noise Linear or Hybrid topology preferred for logic boards. |

Defining Industrial Grade: Beyond the Spec Sheet

The 24/7 Duty Cycle Standard

A hobbyist supply may offer "30V 10A" for $100, but it will fail under continuous load. An Industrial Variable AC DC Power Supply is engineered for a 100% duty cycle at maximum rated ambient temperature (often 40°C+).

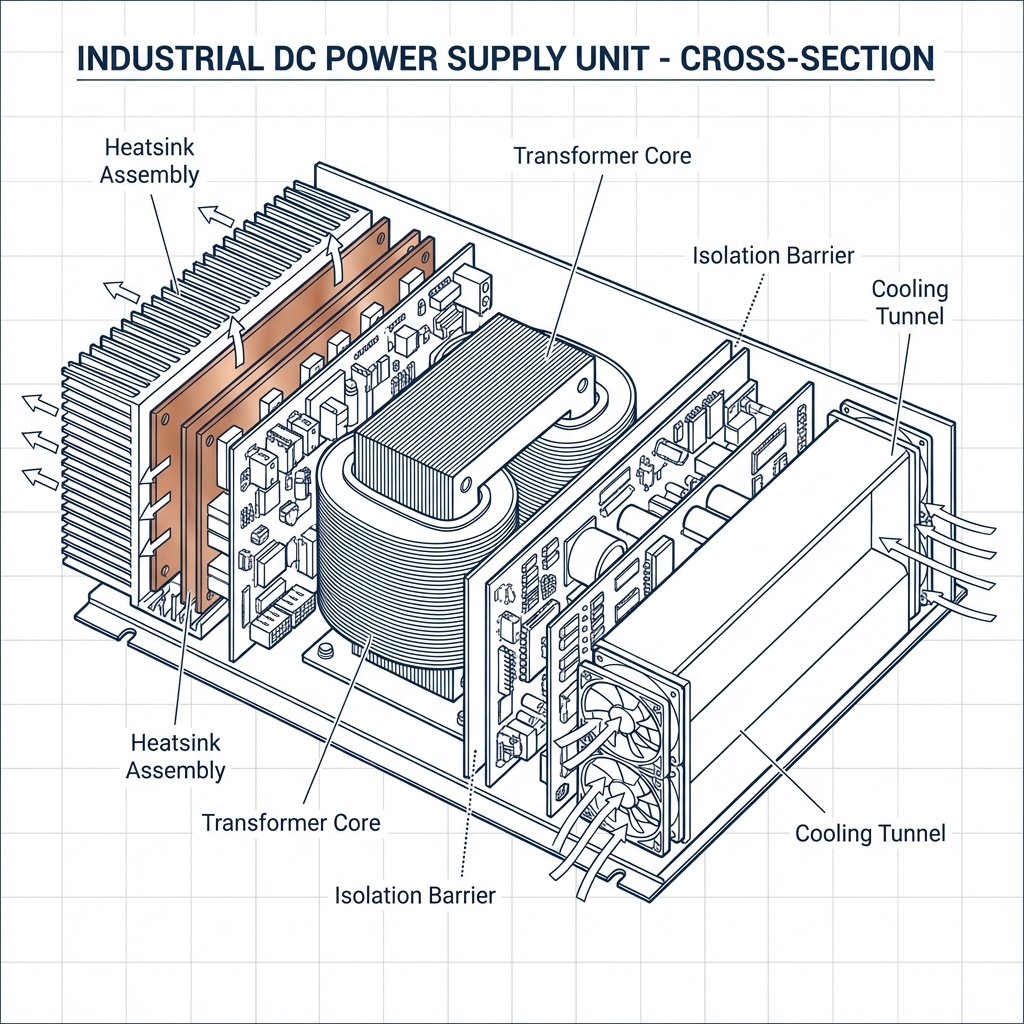

- Thermal Headroom: Industrial units like the eTM-30200 Series (200A) utilize oversized heatsinks and intelligent tunnel cooling to prevent thermal runaway during long-duration plating or burn-in tests.

- Galvanic Isolation: Critical for protecting downstream ATE systems. High-end topologies ensure the DC output is floating and isolated from the AC mains ground loop.

Fig 1: Industrial-Grade Power Supply Internal Architecture

ATE Integration & Programmable Protocols

In 2026, manual knob-turning is obsolete for production lines. Modern Programmable Power Supplies must integrate seamlessly into Automated Test Equipment (ATE) racks.

SCPI & Remote Control

Standard Commands for Programmable Instruments (SCPI) over RS232, RS485, or LAN allow for millisecond-level voltage stepping. This is essential for simulating battery drain curves or solar array IV characteristics. Series like the eTM-L1503SPL offer high-precision readback (>5 digits) directly to the host PC, eliminating the need for external multimeters.

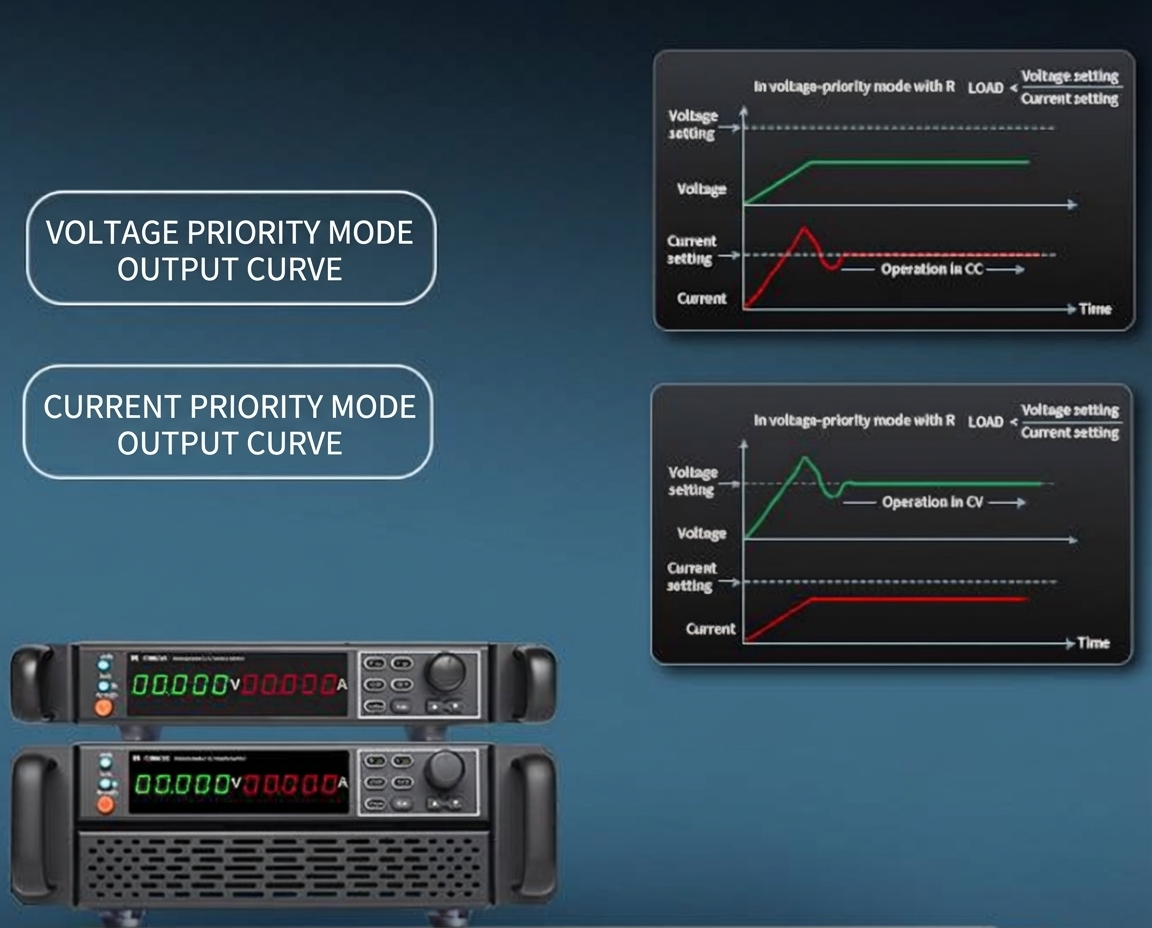

Furthermore, distinct CC/CV Priority Modes (as shown in Fig 2) are critical for protecting sensitive DUTs from voltage overshoot. Unlike generic supplies, this feature allows engineers to prioritize current loop response for LED testing or voltage loop for battery charging.

Fig 2: ATE Integration and CC/CV Priority Mode Visualization

Topology Selection: Linear vs. High-Power Switching

| Feature | Linear (LPS) | Switching (SMPS) |

|---|---|---|

| Ripple / Noise | <1mVrms (Ultra Clean) | <30mVp-p (Good) |

| Efficiency | Low (40-50%) - Runs Hot | High (85-95%) - Cool |

| Power Density | Heavy / Bulky | Compact / Lightweight |

| Ideal Application | Audio, RF, Precision Calibration | High Current Plating, Motor Driving, LED Aging |

For most high-power industrial applications (>1kW), modern Switching topologies are the standard due to efficiency. For reference standards, Linear remains king.